As we celebrate Manufacturing Day tomorrow, we focus this blog post on America’s energy revolution that has ushered in a manufacturing renaissance.

The oil and natural gas shale boom has helped stimulate chemical manufacturing and spur new investments within the industry, which includes plastics manufacturing.

According to the American Chemistry Council (ACC), there have been 333 projects, valued at a total of $202.4 billion, in capital investments announced since 2010. Almost half of the investments are completed or under construction while another 41% are already in the planning phase.

The ACC predicts that the projects – which include new facilities, expansions, and factory re-starts – could create over 70,000 direct jobs and nearly 400,000 indirect jobs in the United States. Overall, the projects will create approximately $337 billion in economic output.

Manufacturing in the Appalachian Region

The ACC also reports high potential for petrochemicals and plastics manufacturing in the Appalachian region specifically, including Ohio, Pennsylvania, West Virginia, and Kentucky.

The report predicts $36 billion in capital investment by 2025. This includes $32.4 billion in petrochemicals, resins, and derivatives, plus $3.4 billion in plastics products alone. Over 101,000 jobs could be created and supported through direct, indirect, and payroll-induced jobs.

The ACC notes, however, that energy infrastructure that allows for a storage and pipeline network for natural gas liquids and chemicals, plus an efficient regulatory permitting process, is important to energy growth in the region.

How it Works

Natural gas and natural gas liquids (NGLs) are important feedstocks for chemical production in the United States. A feedstock is an unprocessed material used in manufacturing. For chemical manufacturing in particular, a feedstock is a chemical used in a large-scale chemical reaction to create refined products.

Natural gas is primarily made of methane, but can also include NGLs like propane, butane, and ethane.

Methane, which makes up a vast majority of dry gas, is used to create methanol. Methanol can be turned into chemicals like acetic acid and formaldehyde, which are used in products like adhesives, paints, solvents, and windshield washer fluid. Methanol manufacturing plants have relocated to the United States in response to low natural gas prices, creating direct and indirect jobs.

Ethane, another component of natural gas, is used to create ethylene, a major building block of plastics. Again, lower prices of ethylene and polyethylene have spurred the creation of ethane cracker plants, which turn ethane into ethylene. Learn more about “cracking” here.

Manufacturing Industry’s Energy Consumption

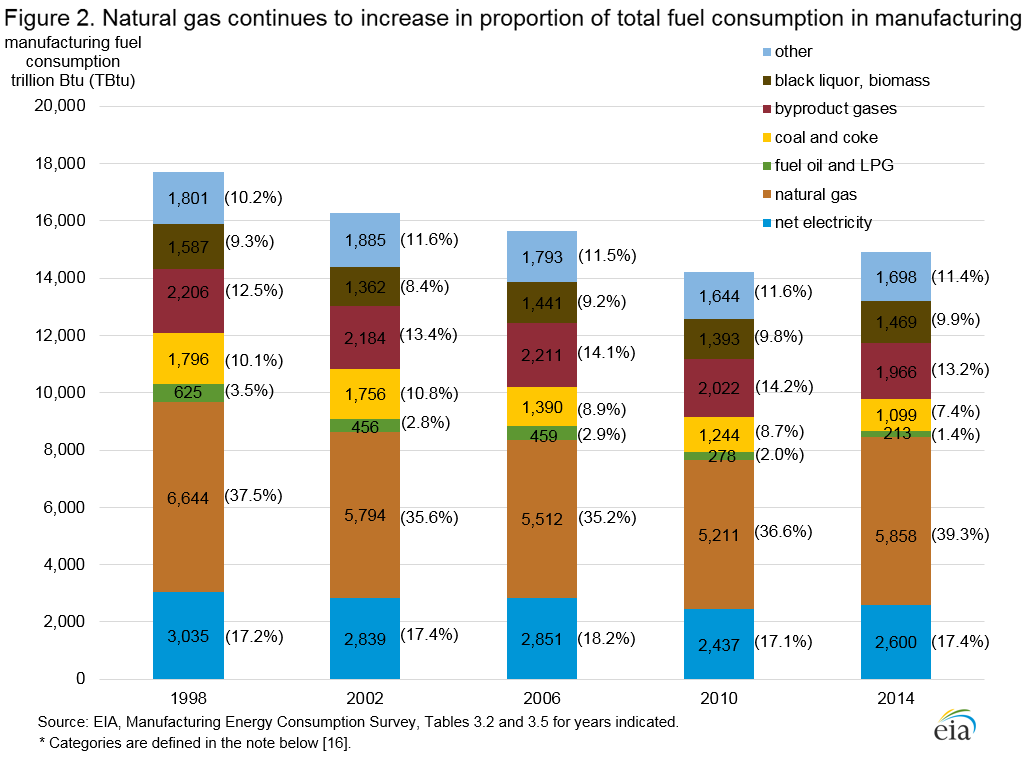

Aside from the major role that oil and natural gas liquids play in plastics production, natural gas is helping the manufacturing industry in another way: energy intensity.

The Manufacturing Energy Consumption Survey estimated that between 2010 and 2014, natural gas use in the manufacturing industry increased. Natural gas boilers that produce energy create fewer pollutants. The study suggests that this enables manufactures to have cleaner operations, therefore avoiding expenses that come from mitigating pollutants or follow-ups on regulations by the Environmental Protection Agency.